With our solid track record and knowhow spanning a wide range of industries, we are able to extensively support your company's logistics environmental improvements.

DAIICHI KOGYO utilizes conveyor systems to provide solutions for the various requests from customers, such as "I want to rapidly send large volumes of packages across Japan and overseas," or "I want to automate my factory lines."

The mail order industry, which as you know has grown explosively in recent times, now has to deliver products ordered online as quickly as possible.

We are also providing systems capable of sorting mass volumes of articles and contributing to speeding up logistics processes.

While developing new types of machines every now and then, we have continued to provide unique, best-fit systems. Our lineup of conveyor systems contains many devices we have developed over the years to match the needs of our customers from a wide range of industries, including parcel-delivery centers, newspaper printing centers, large post offices, banks, and hospitals.

The following describes one example of our systems as a case model.

The following describes one example of our systems as a case model.

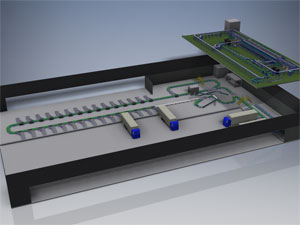

This case model is imagined for use in a logistics center for the parcel-delivery business or the like.

As for the function of the center, a Wave Sorter is installed on the first floor of the center to sort the comparatively large articles. The outgoing articles are discharged in 30 directions, while the incoming articles arrive from six trucks. Also, a Vertical Cross Belt Sorter is installed on the second floor to sort the comparatively small articles such as envelope-sealed documents.

Using this model, we will describe our systems.

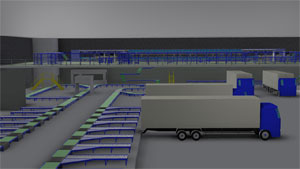

Incoming articles arrive on trucks from outside.

Incoming articles arrive on trucks from outside.

The incoming articles are loaded onto the conveyor.

Articles such as envelope-sealed documents are loaded onto a conveyor at the back.

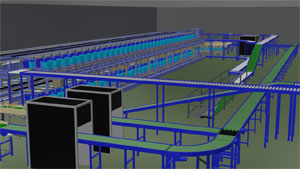

After being loaded on the conveyor, articles are scanned by barcode readers and sorted to the discharge stations registered in the system.

After being loaded on the conveyor, articles are scanned by barcode readers and sorted to the discharge stations registered in the system.

After articles have been loaded onto the conveyor as incoming articles, they are conveyed to the second floor along an upward sloping conveyor.

After articles have been loaded onto the conveyor as incoming articles, they are conveyed to the second floor along an upward sloping conveyor.

On the second floor, each article is separated and scanned by a barcode reader. The articles are loaded onto a sorter and sorted to the discharge station registered in the system. At the discharge stations, containers specially designed for sorting are installed.

After sorting has been completed, the specially designed containers are sent off.

The specially designed containers are conveyed down to the first floor to merge into the conveyor line of the Wave Sorter.

The Conveyor System Division also showcases its systems at trade exhibitions.

The main exhibitions we attend are Logis-Tech Tokyo and the Japan Newspaper Production Show (JANPS).

The Conveyor System Division also showcases its systems at trade exhibitions.

The main exhibitions we attend are Logis-Tech Tokyo and the Japan Newspaper Production Show (JANPS).

2005 JANPS: Vertical Cross Belt Sorter

2006 Logis-Tech Tokyo: Vertical Cross Belt Sorter

2007 JANPS: Roller rotary-type sorting device and transfer device

2008 Logis-Tech Tokyo: Wave Sorter

2009 JANPS: Wave-system rotary transfer device

2010 Logis-Tech Tokyo: Non-contact power-supply system Cross Belt Sorter

2012 JANPS: Only video panel display

2012 Logis-Tech Tokyo: Vertical Cycle-System Cross Belt Sorter

2014 Logis-Tech Tokyo: MarbiQ Sorter (small article sorting using image recognition)

2015 JANPS: Only video panel display

2016 Logis-Tech Tokyo: Sorting by a Wave Sorter using SCARA robot and image recognition